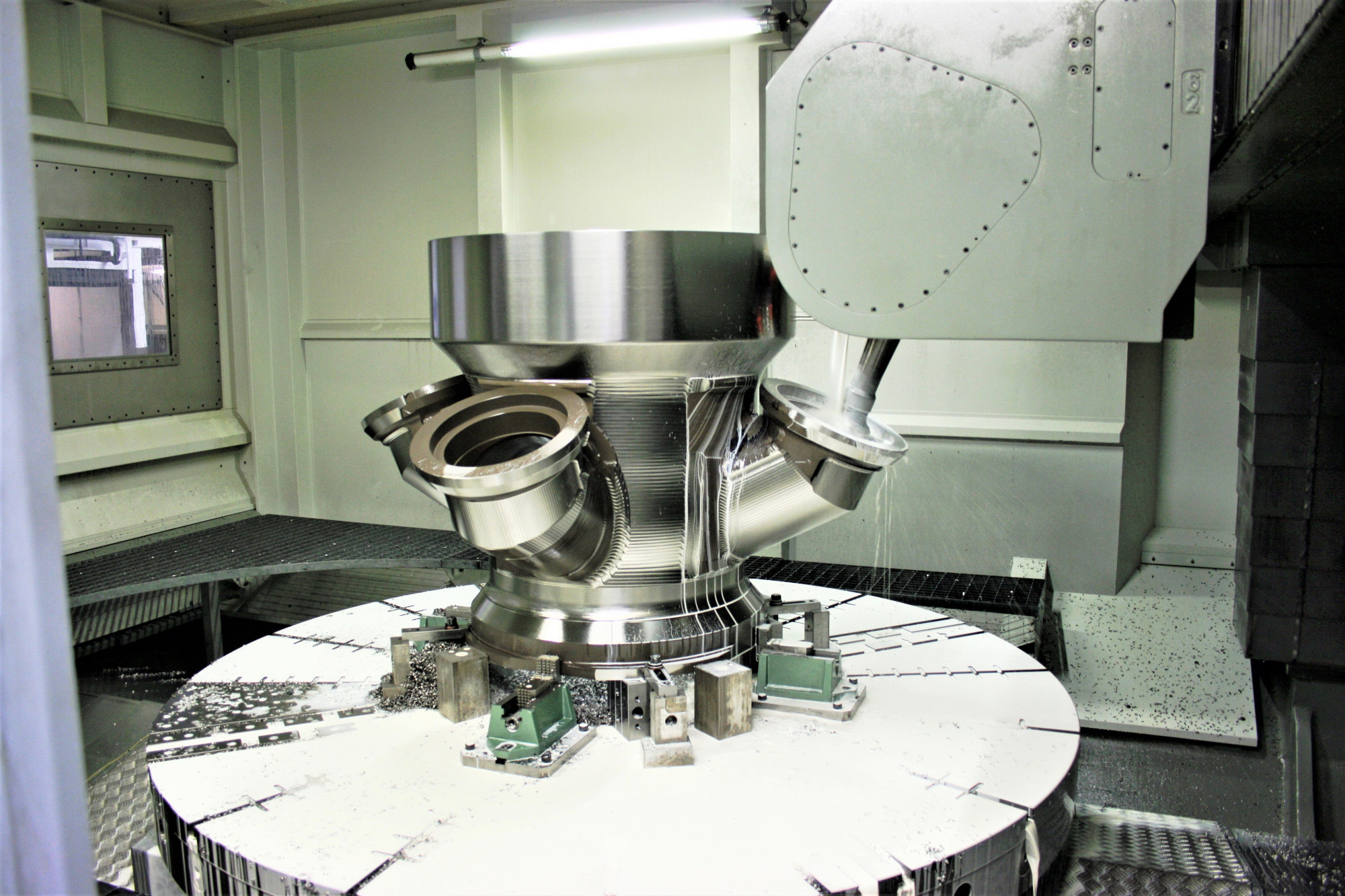

Ready for Your Most Complex Manufacturing Projects

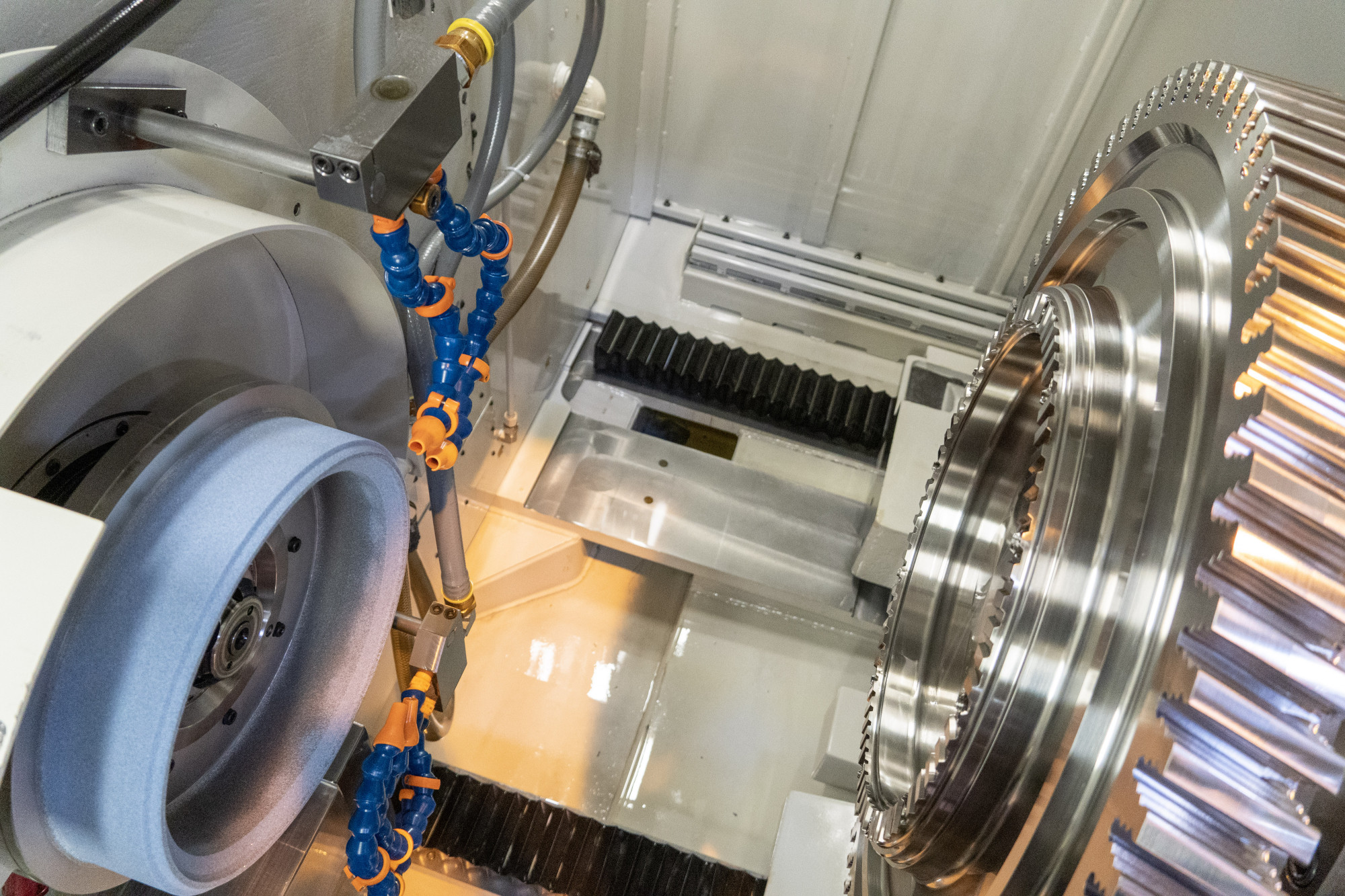

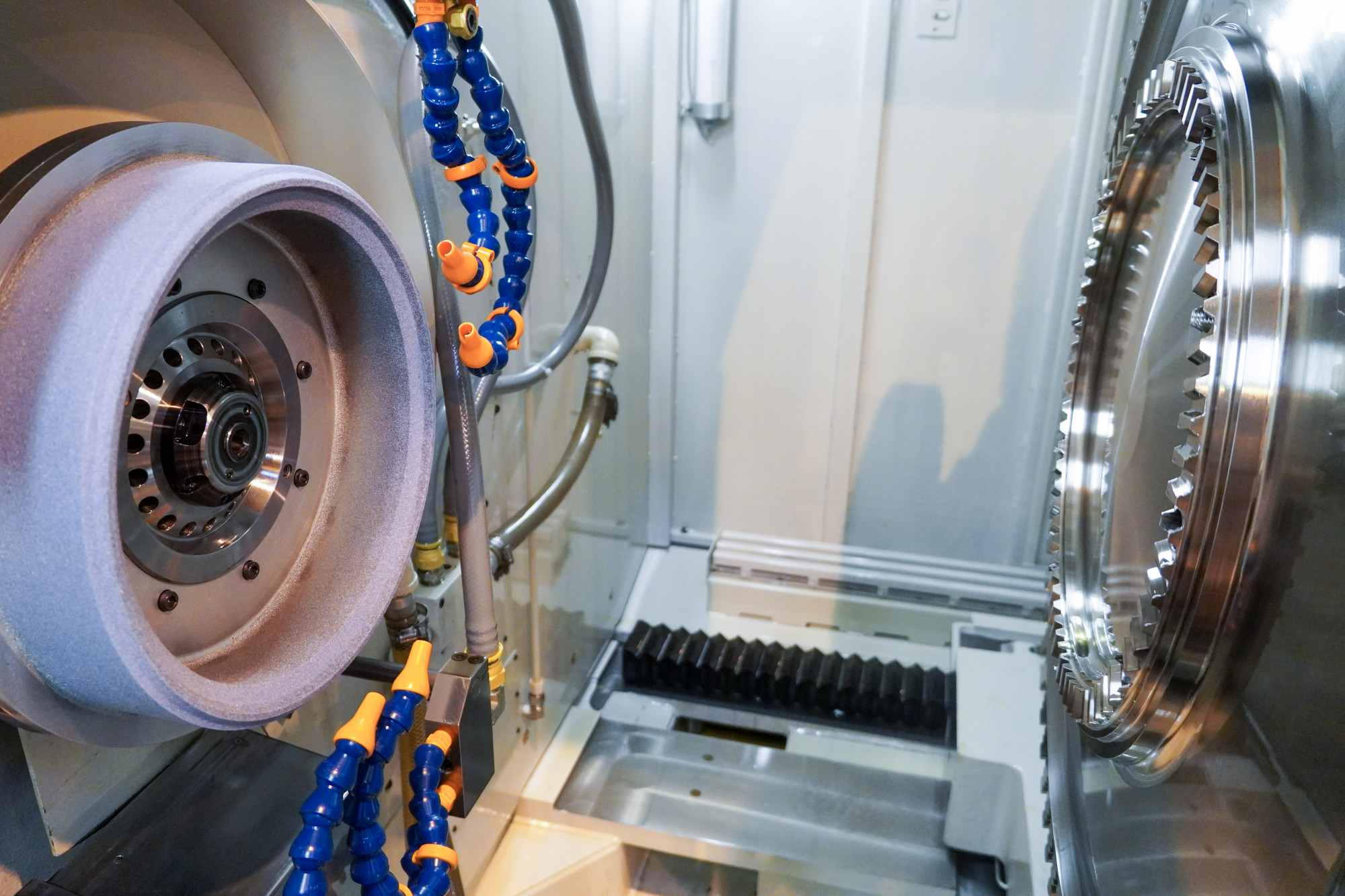

Our large 5-axis precision milling and turning capabilities are ideal for any project requiring tight tolerances and excellent finishes.

The oversized components we machine are often the foundation of mission critical projects and large assemblies for major customers in industries such as aerospace, energy, and space. From turbine cases to nuclear core shrounds to marine propulsion components, our highly skilled workforce uses the latest large machining, tooling and systems technology to deliver incredible value.

We are prepared to help our customers achieve competitive excellence and win new business.

Whatever the project, we enjoy partnering with customers to overcome every challenge imaginable, exceed expectations and ensure success.

Discover why we are your preferring manufacturing partner.

Why MetalexFrom the start, we have specialized in assembling the most advanced manufacturing technology in the world to help our customers solve their toughest challenges on-time, under budget and with exceptional quality.

View ProjectsOur large array of advanced services allows us to deliver manufacturing solutions for the most advanced projects in the world.

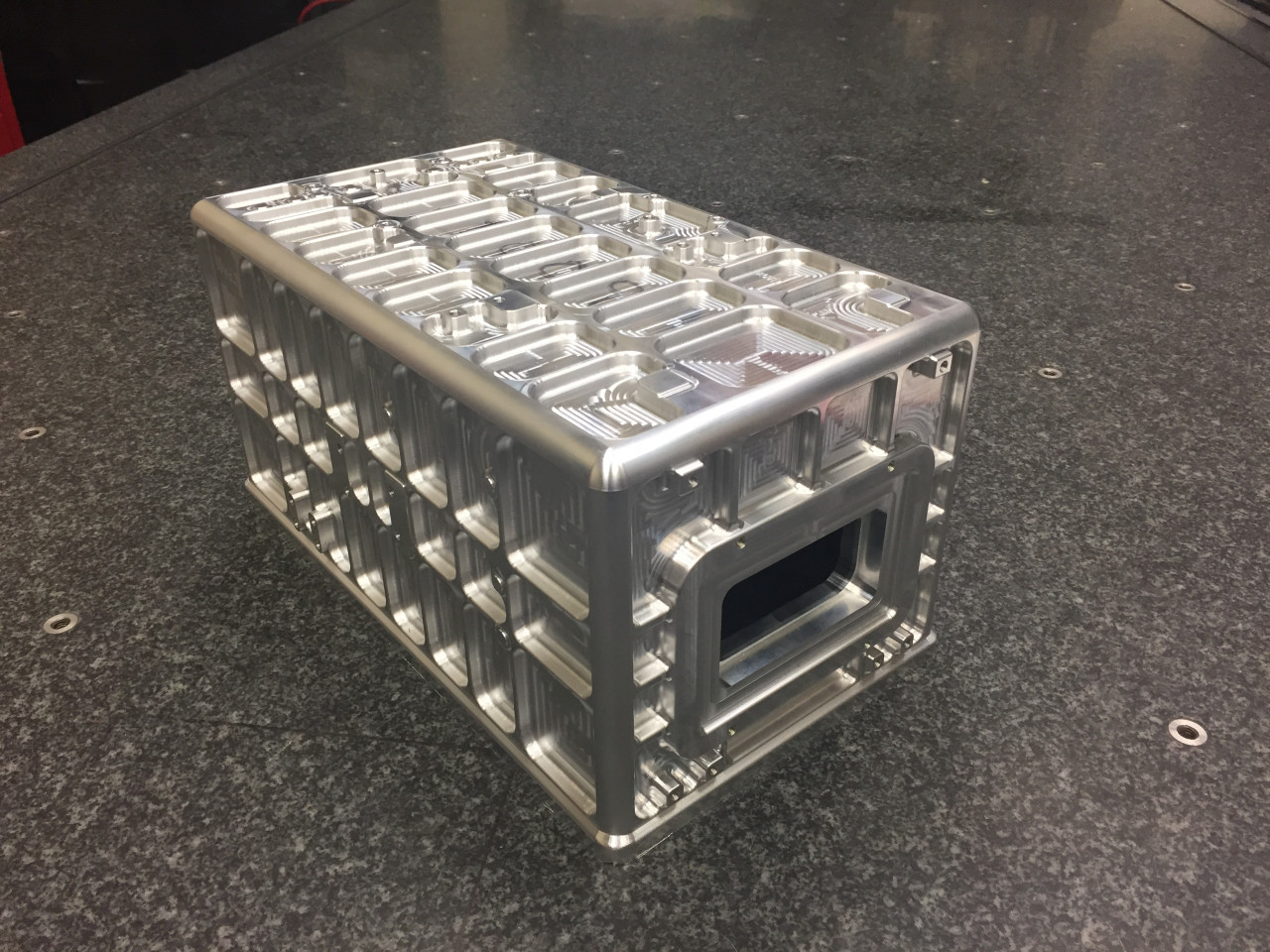

From massive oversized parts weighing hundreds of tons, to small components with complex geometry that can be held in the palm of your hand, our team of experts leverage cutting-edge technology to ensure customer success.

View All ServicesServing Diverse Industries

We are ready to support your mission critical projects 24 hours a day, 7 days a week.

Learn MoreOur top-of-the-line facilities, team and equipment are some of the most advanced in the world

Selecting Metalex for your project means having a true manufacturing partner that is committed to delivering the best total value on innovative projects and building lasting relationships based on shared success.

Check out some of our favorite projects to date and learn why Metalex is your choice partner.

Successful companies have a clear mental picture of how their organization looks when operating at its absolute best. At Metalex, this vision is achieved through what we call Interactions Without Boundaries or “IWB”.

The “IWB” acts as our “playbook” for every leader and team member, clearly defining roles and responsibilities with an emphasis on effectively communicating expectations on a daily basis.

IWB provides strategic clarity and empowers our team to capitalize on each individual's unique skill set. It ensures we are delivering the best possible value for our customers as well as providing job satisfaction for our team members.

Read More

Self-Directed Workforce

Our culture is reflected in our flat organizational structure which is supported by our values of mutual trust and teamwork. At Metalex, we have no supervisors. We are a self-directed workforce of strategic, unified partners—unlike the traditional boss / employee structure. Team members are expected to work with a can-do attitude, working as one unit for the success of our customers..jpg)

Culture & Values

We are committed to quality, craftsmanship and service. Our values define who we are and guide who we aspire to become. Our culture is built on character, trust and teamwork and our culture is what sustains us today and drives us into tomorrow.Join a culture that is committed to loyalty, continuous improvement, innovation and quality. We are always looking for brilliant, hardworking individuals who are ready to take the next step in their career and join us in solving some of the biggest challenges out there.

Learn MoreMetalex is continuously developing and implementing cutting edge manufacturing technology to deliver exceptional quality, service, on-time delivery and affordability. Learn more about what Metalex is doing below.

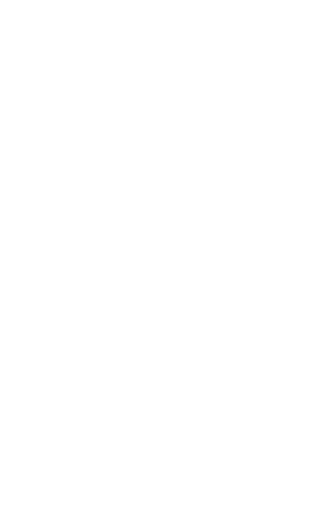

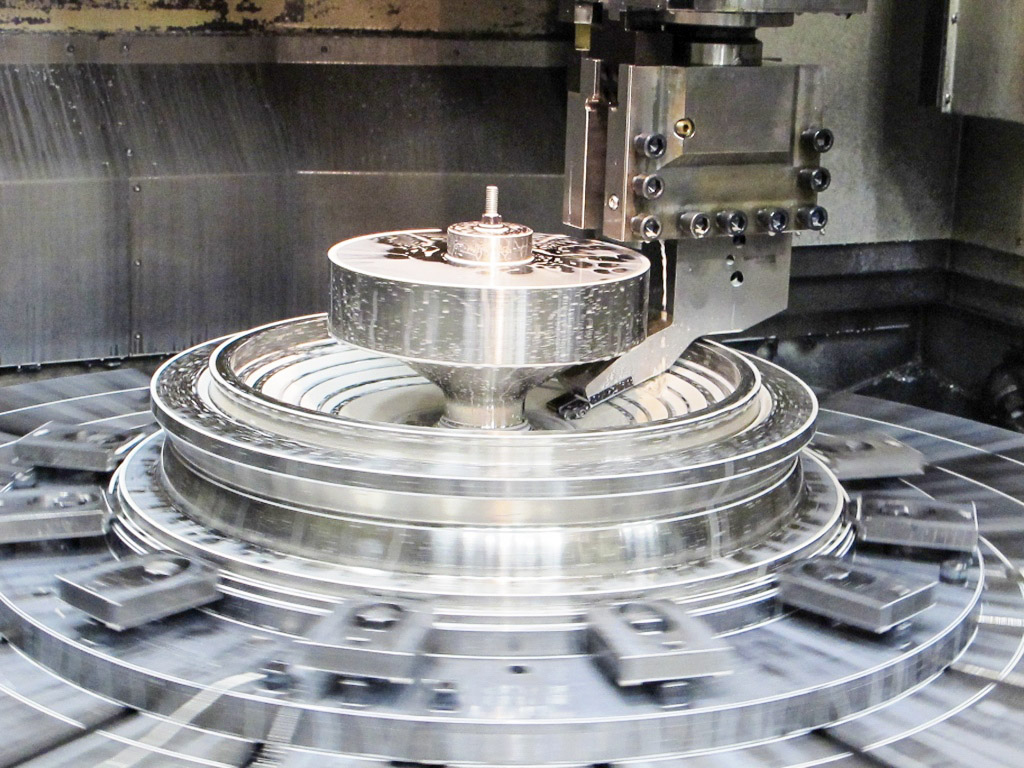

We Are Growing Our Curvic Grinding Expertise

Metalex’s unique combination of specialized equipment, technical expertise allows us to produce extremely accurate Curvic Couplings needed for critical rotating components across a variety of industries.

Curvic Grinding

New High Bay Facility Construction Complete

In 2021, Metalex completed construction of a new 45,000 sq. ft. environmentally controlled facility designed for precision manufacturing and assembly of large complex components for a diverse group of customers and industries.

Large Machining.jpg)

Metalex Receives NASA Space Flight Award

Metalex is proud to be a recipient of NASA Space Flight Awareness Award. Metalex was nominated for this award by our customers for exceptional quality, on-time delivery and affordability on mission critical hardware.

Customer Recognition

Working at Metalex

Quality, craftsmanship and service are the culture and character of our company. We build trust through honest and open communication with teammates, customers and business partners. We do what we say and say what we do – this is what sets our people and company apart. learn more about a Career at Metalex.

Careers

Metalex is Recognized by the State of Ohio for Contributions to Strengthening Ohio’s Business Community

Metalex is recognized by the State of Ohio for Contributions to Strengthening Ohio's Business Community by the Ohio Secretary of State.

Continue Reading

Metalex is recognized by Vetrepreneur Magazine for Supporting the hiring and training of US Military Veterans, which accounts for approximately 15% of our total workforce.

Metalex is recognized in Vetrepreneur magazine, a publication dedicated to veteran owned businesses for hiring and training of US Military Veterans.

Continue Reading.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_(1).jpg)

.jpg)